SIMULATION|Finite Element Analysis

Tightly integrated with SOLIDWORKS CAD, SOLIDWORKS Simulation solutions and capabilities

can be a regular part of your design process—reducing the need for

costly prototypes, eliminating rework and delays, and saving time and

development costs.

Efficiently optimize and validate each design step using fast-solving, CAD integrated SOLIDWORKS Simulation to ensure quality, performance, and safety.

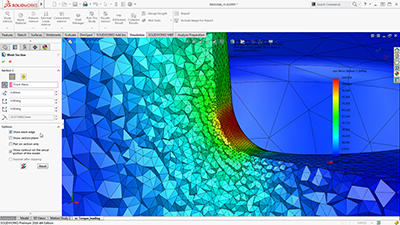

Finite Element Modeling

SOLIDWORKS Simulation uses the displacement formulation of the finite

element method to calculate component displacements, strains, and

stresses under internal and external loads. The geometry under analysis

is discretized using tetrahedral (3D), triangular (2D), and beam

elements, and solved by either a direct sparse or iterative solver.

SOLIDWORKS Simulation also offers the 2D simplification assumption for

plane stress, plane

strain, extruded, or axisymmetric options. SOLIDWORKS Simulation can use either an h or p adaptive element type, providing a great advantage to designers and engineers as the adaptive method ensures that the solution has converged.

strain, extruded, or axisymmetric options. SOLIDWORKS Simulation can use either an h or p adaptive element type, providing a great advantage to designers and engineers as the adaptive method ensures that the solution has converged.

In order to streamline the model definition, SOLIDWORKS Simulation

automatically generates a shell mesh (2D) for the following geometries:

- Sheet metal body—SOLIDWORKS Simulation assigns the thickness of the shell based on the 3D CAD sheet metal thickness, so Product Designers can leverage the 3D CAD data for Simulation purposes.

- Surface body

For shell meshing, SOLIDWORKS Simulation

offers a productive tool, called the Shell Manager, to manage multiple

shell definitions of your part or assembly document. It improves the

workflow for organizing shells according to type, thickness, or

material, and allows for a better visualization and verification of

shell properties.

SOLIDWORKS Simulation also offers the 2D simplification assumption

for plane stress, plane strain, extruded, or axisymmetric options.

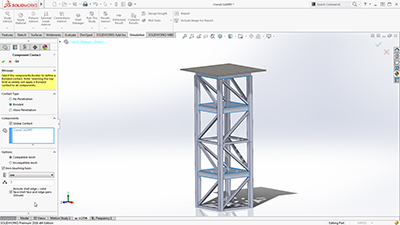

Product Engineers can simplify structural beams to optimize

performance in Simulation to be modeled with beam elements. Straight,

Curved, and tapered Beams are supported. SOLIDWORKS Simulation

automatically converts structural members that are created as weldment

features in 3D CAD as beam elements for quick setup of the simulation

model.

Users can specify local mesh control at vertices, edges, faces, components, and beams for a more accurate representation of the geometry.

Integrated with SOLIDWORKS 3D CAD, finite element analysis using SOLIDWORKS Simulation knows the exact geometry during the meshing process. And the more accurately the mesh matches the product geometry, the more accurate the analysis results will be.

Finite Element Analysis (FEA)

Since the majority of industrial components are made of metal, most

FEA calculations involve metallic components. The analysis of metal

components can be carried out by either linear or nonlinear stress

analysis. Which analysis approach you use depends upon how far you want

to push the design:

- If you want to ensure the geometry remains in the linear elastic range (that is, once the load is removed, the component returns to its original shape), then linear stress analysis may be applied, as long as the rotations and displacements are small relative to the geometry. For such an analysis, factor of safety (FoS) is a common design goal.

- Evaluating the effects of post-yield load cycling on the geometry, a nonlinear stress analysis should be carried out. In this case, the impact of strain hardening on the residual stresses and permanent set (deformation) is of most interest.

The analysis of nonmetallic components (such as, plastic or rubber parts) should be carried out using nonlinear stress analysis

methods, due to their complex load deformation relationship. SOLIDWORKS

Simulation uses FEA methods to calculate the displacements and stresses

in your product due to operational loads such as:

- Forces

- Pressures

- Accelerations

- Temperatures

- Contact between components

Loads can be imported from thermal, flow, and motion Simulation studies to perform multiphysics analysis.

Mesh definition

SOLIDWORKS Simulation offers the capability to mesh the CAD geometry

in tetrahedral (1st and 2nd order), triangular (1st and 2nd order),

beam, and truss elements. The mesh can consist of one type of elements

or multiple for mixed mesh. Solid elements are naturally suitable for

bulky models. Shell elements are naturally suitable for modeling thin

parts (such as sheet metals), and beams and trusses are suitable for

modeling structural members.

As SOLIDWORKS Simulation is tightly integrated inside SOLIDWORKS 3D CAD, the topology of the geometry is used for mesh type:

- Shell mesh is automatically generated for sheet metal model and surface bodies

- Beam elements are automatically defined for structural members

So their properties are seamlessly leveraged for FEA.

To improve the accuracy of results in a given region, the user can

define Local Mesh control for vertices, points, edges, faces, and

components.

SOLIDWORKS Simulation uses two important checks to measure the quality of elements in a mesh:

- Aspect Ratio Check

- Jacobian Points

In case of mesh generation failure, SOLIDWORKS Simulation guides the

users with a failure diagnostics tool to locate and resolve meshing

problems. The Mesh Failure Diagnostic tool renders failed parts in

shaded display mode in the graphics area.